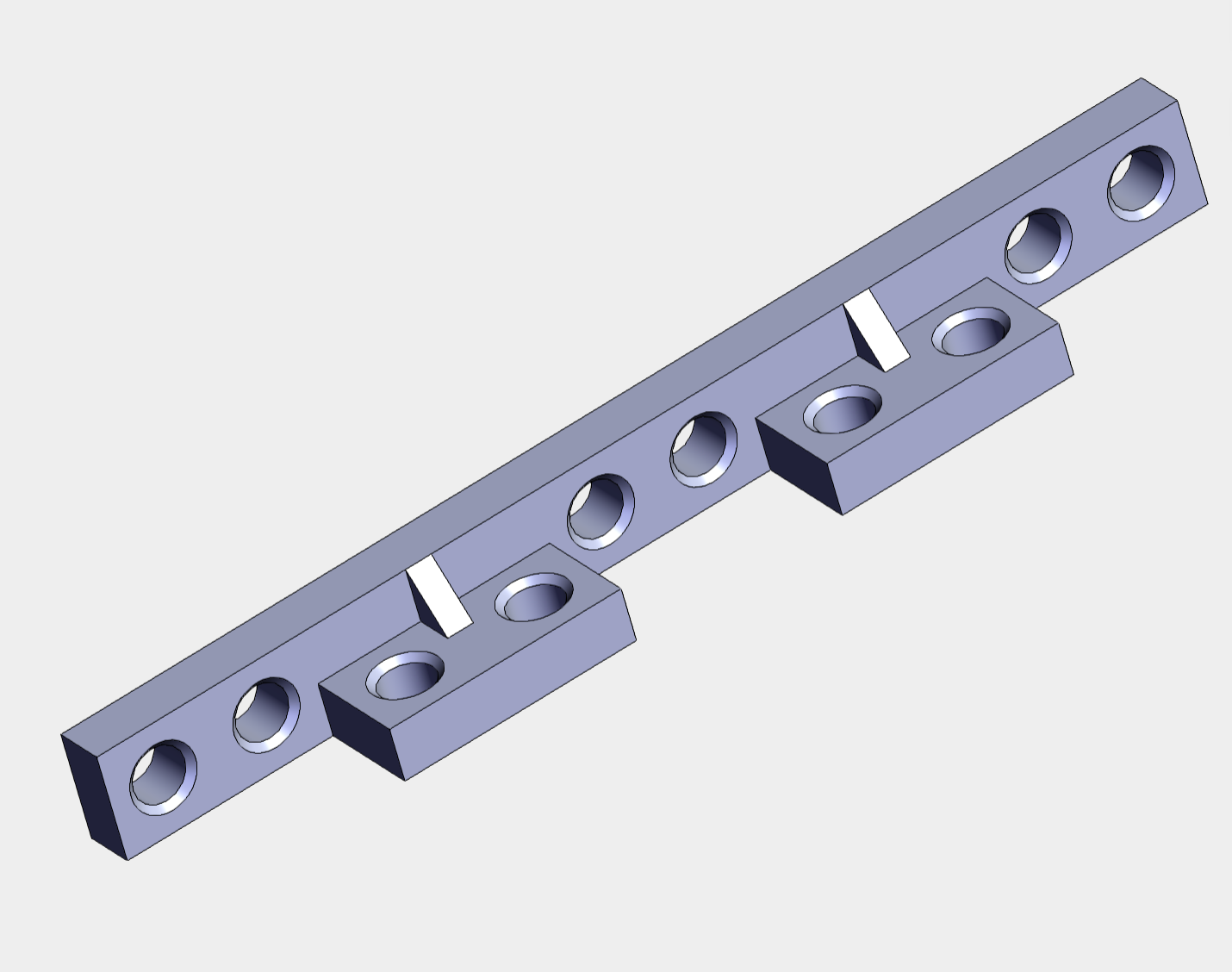

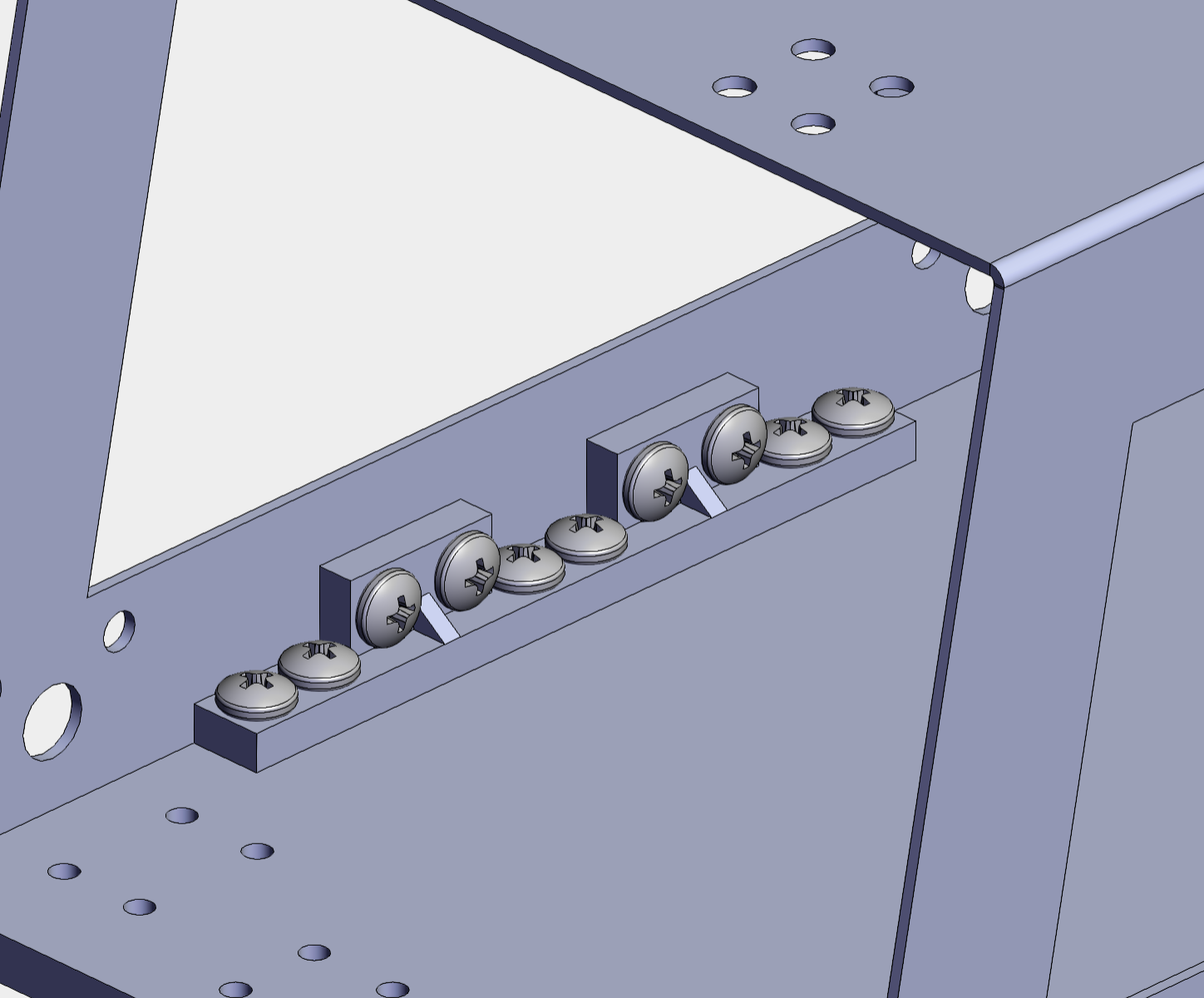

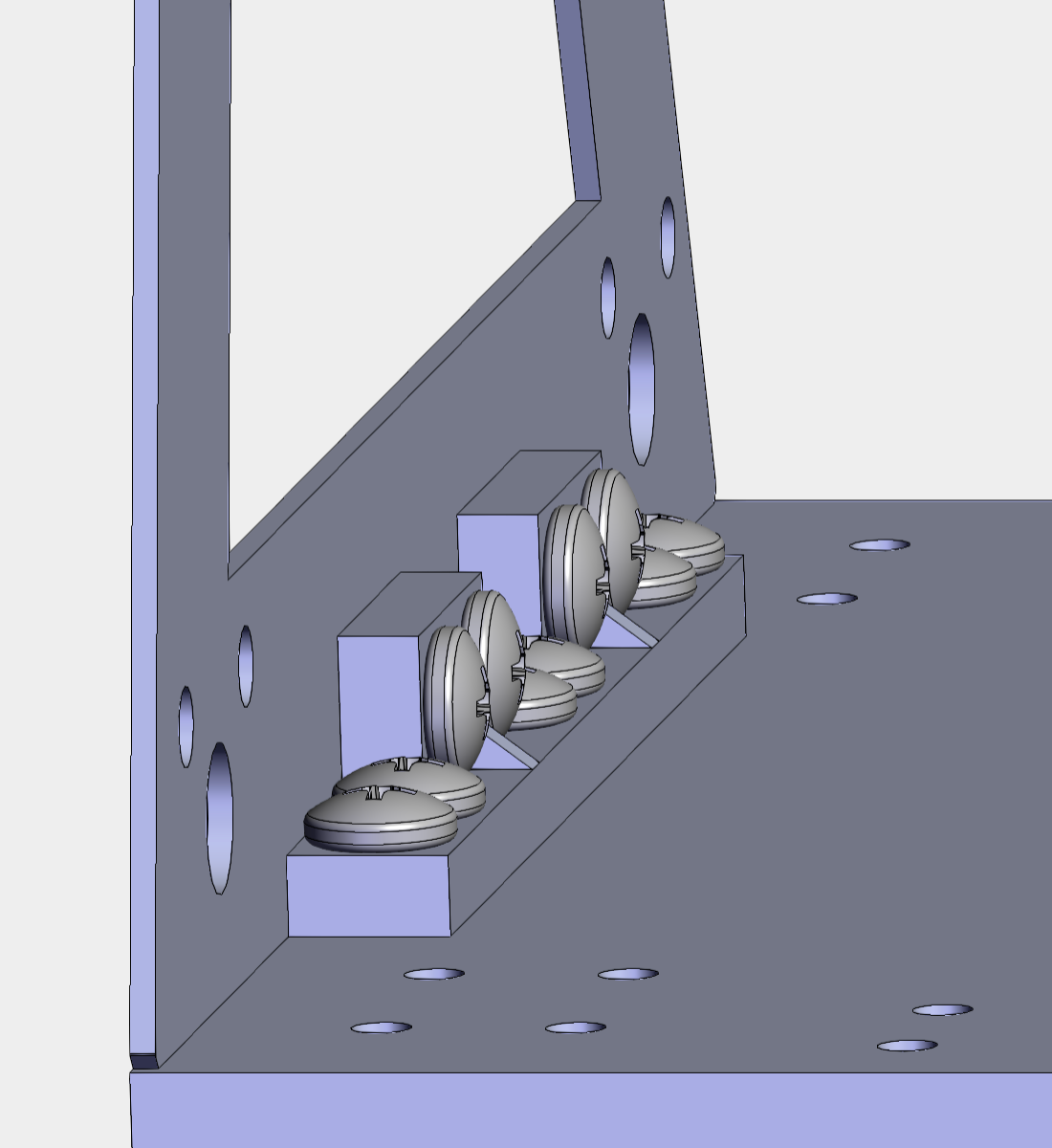

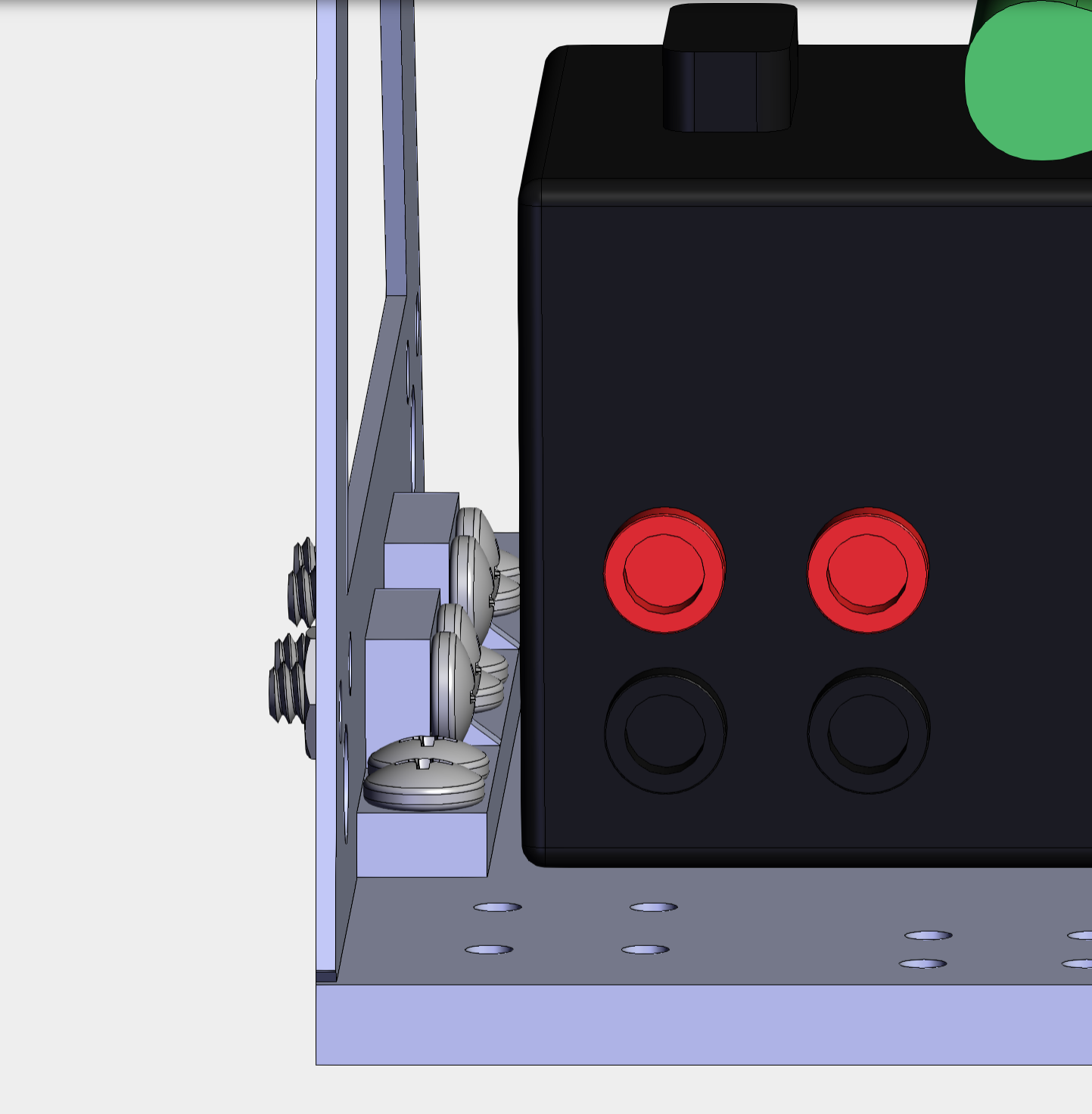

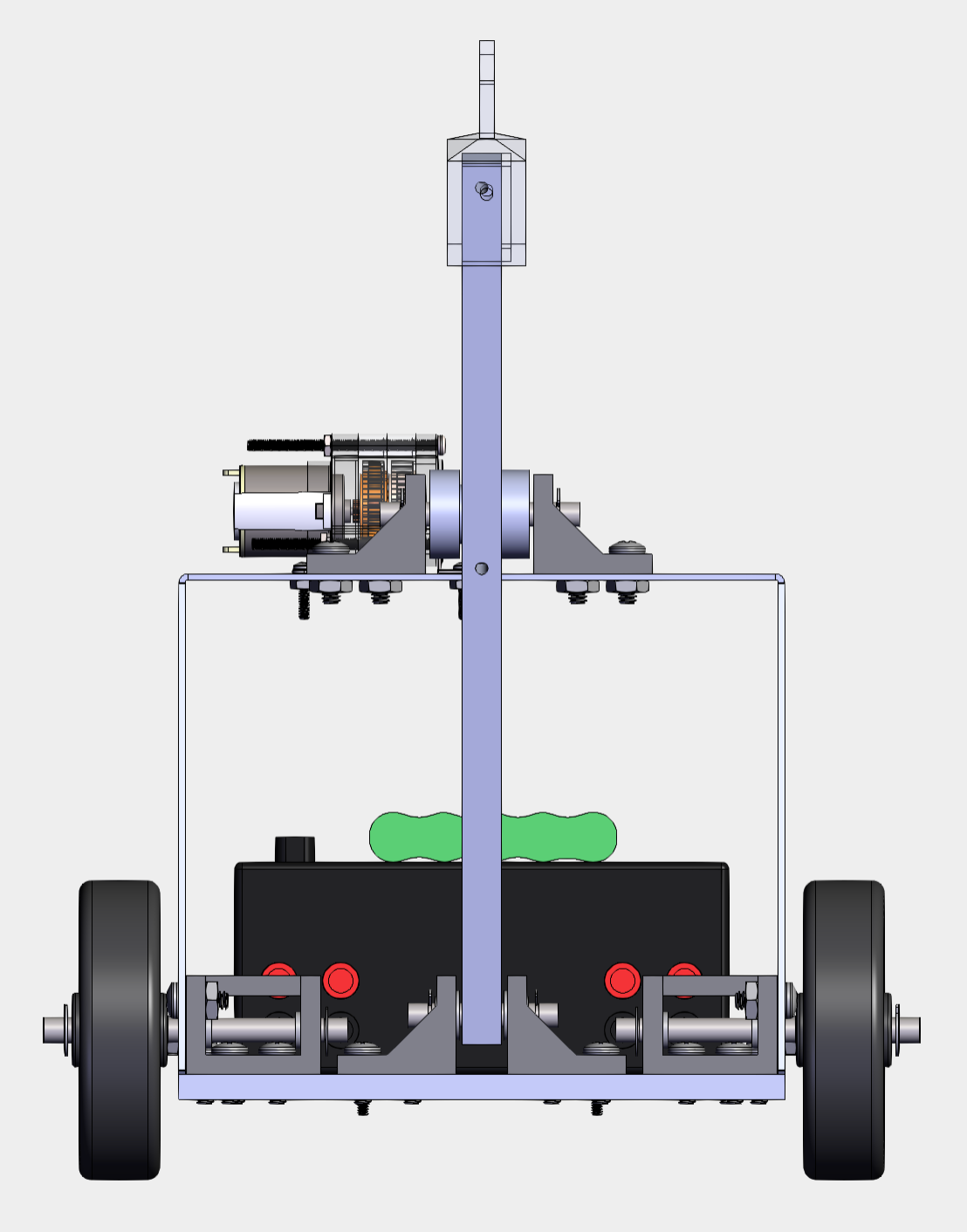

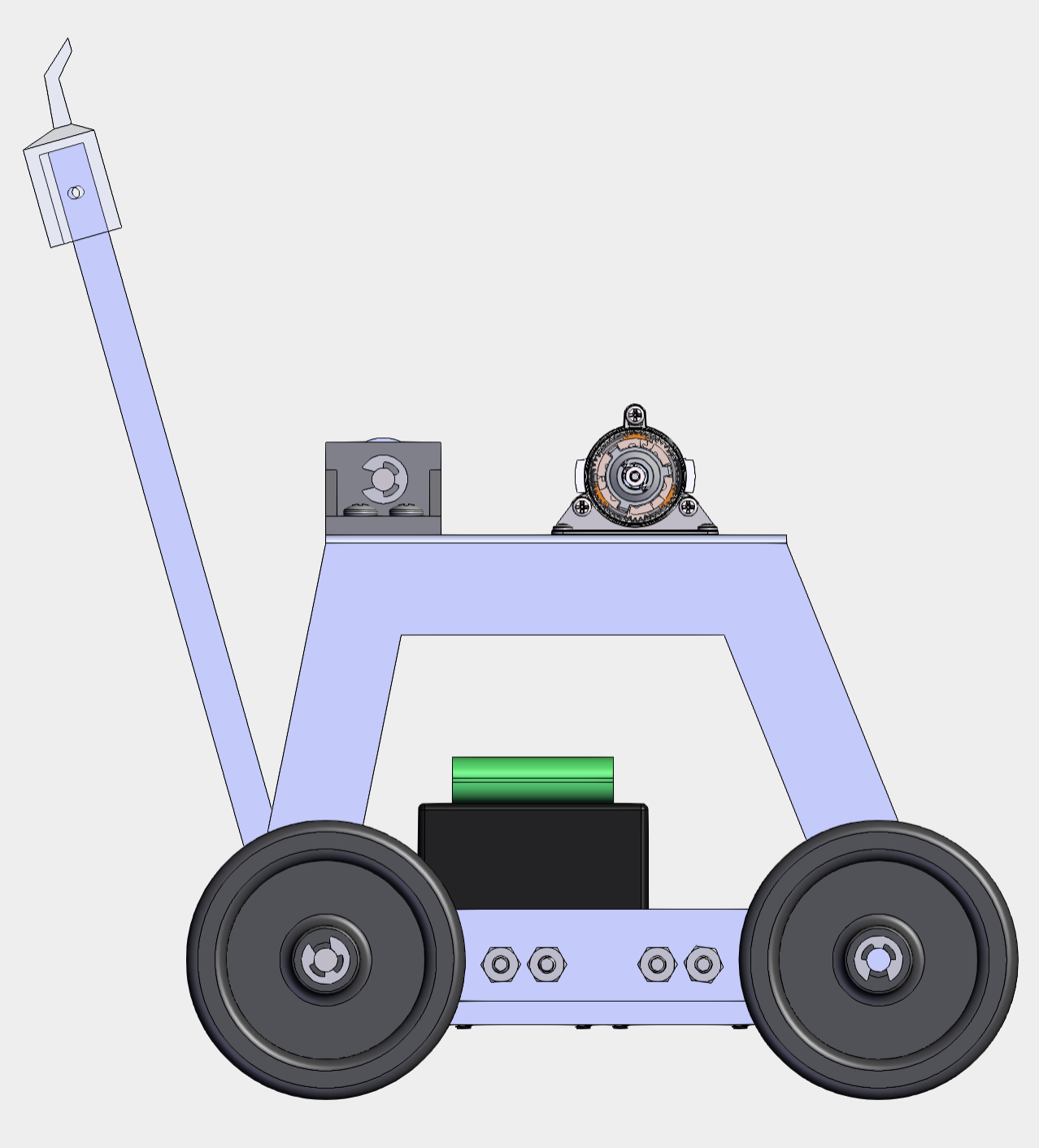

My SolidWorks model of our groups final robot design.

In fall 2021 I took Mechanical Engineering 250: Design and Manufacturing I to get a better understanding of the engineering side of industrial design. Throughout the semester, we designed, manufactured, and built a robot in small groups. I learned SolidWorks to model my group's robot, and had a large part in designing the robot as well. I really enjoyed being pushed to think about design in a more engineering fashion: considering how small design changes would affect the other subsystems of the robot, balancing the need for precise measurements with the need for tolerances, and learning how to manufacture with a mill, lathe, and 3D printing.

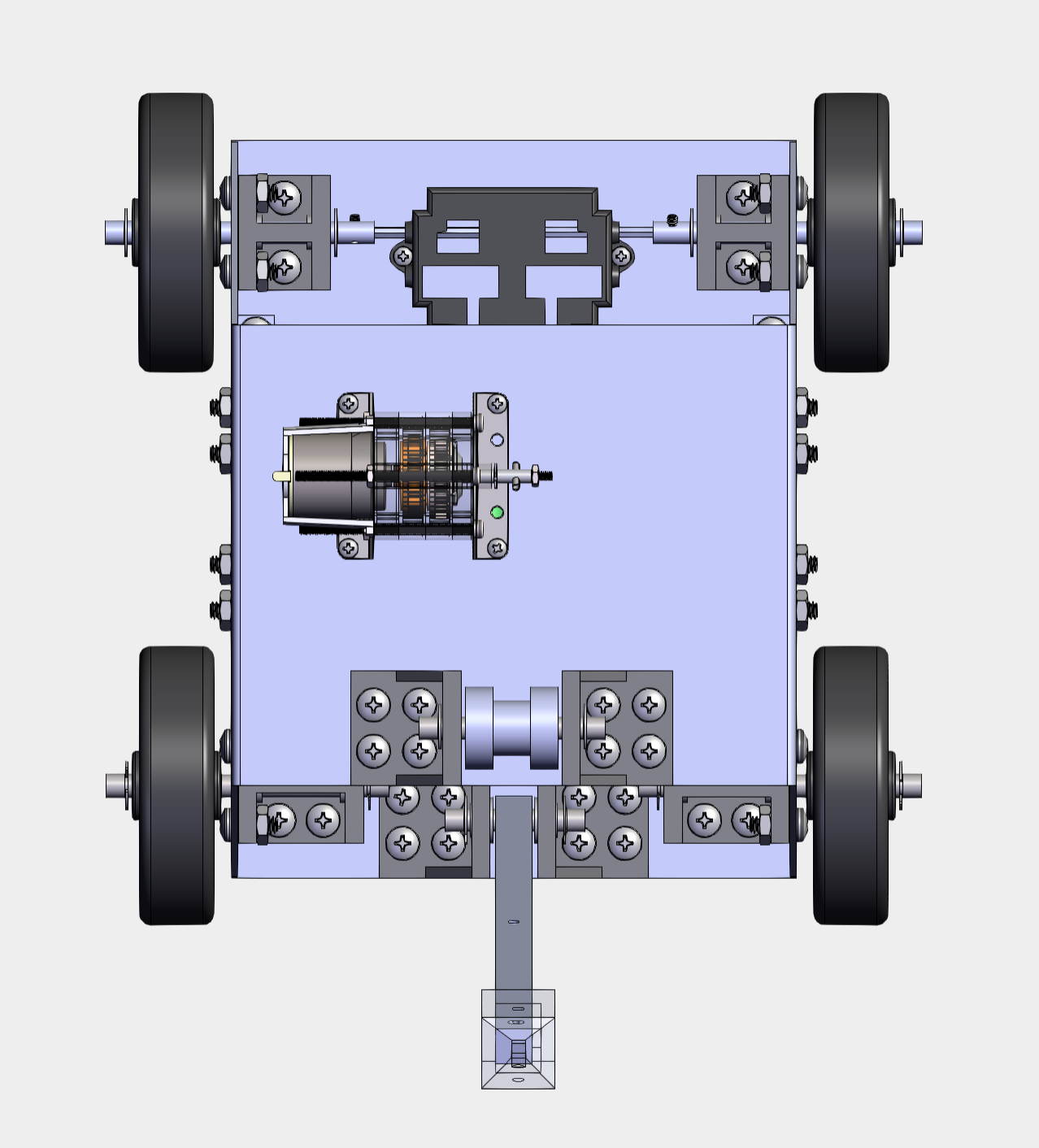

My process model drawing

The element I am most proud of designing is what I called the "worm bracket" seen below. We needed to make connect the base and frame of the robot, but a normal L shaped bracket wouldn't fit between the battery and the frame as there was barely enough space for one screw head, let alone two perpendicular ones. I designed a 3D printed bracket that alternates screw placements vertically and horizontally, so that the vertical bracket side would not block the space of the horizontal screw heads. This solution was very creative and demonstrated strong three dimensional thinking, and was very successful.